|

Lark Parker

Cruiser Member

USA

248 Posts |

Posted - 01/17/2008 : 8:54:17 PM Posted - 01/17/2008 : 8:54:17 PM

|

Pain and Discoloration

DUMB: The first few times I did headlight retainer rings. I was extremely careful. They are frought with danger of catching on the buffing wheel because of their protruding tabs, sharp edges and their shape. Things went well on the first two pair and I gained confidence. You might wonder why I would do such PA job -- but when they show up in a bundle of show car bound stainless, it became a matter of honor to do them.

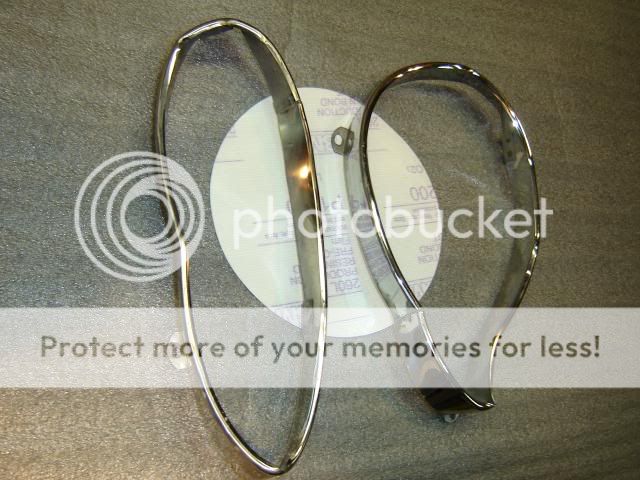

The third pair that I did ended up looking exactly like this. When they jettisoned across the shop and clanged against the wall -- I was a little surprised and almost unhurt. DUMB: Thinking that this was an one time aberration from my usual skillful handling -- I repeated the exercise with the second ring. Yes, I did the same stupid thing again with the same result. But hey, as Jack Nicholson would say, four out of six ain't bad.

Then I hung them both rings on the wall as a constant safety reminder.

(I had a good substitute pair that I didn't even charge him for.)

For those that haven't used a strong buffing wheel the force of the wheel can cause the operator to get cut and also create stainless projectiles.

The smallest pieces are the most dangerous. My body shop mentor once showed me a piece of wadded up Ford drip rail stainless that he did. It wrapped around the buffer shaft with his hand trapped. He made it to the switch and leather gloves saved him from severe damage.

The safest way to refinish light rings is to mount them on a board with three wood screws. The board provides a safe way to handle it and also blocks the buffing wheel from the ring's edge.

I have done drip trail by inserting and holding a strip of somewhat sturdy metal inside the stainless. A strip about three inches wide gives you something to hang onto.

For my own cars, in general, I would not refinish either the light rings or the drip rail. The gain in appearance is doubtful for the risk of damage to the pieces involved. For the drip rail this includes the removal and reinstalling process. Some have been done successfully, but probably not by a bodyman going to his first prom. You might want to reconsider those pieces you might be taking on as a learning ground.

Always wear gloves when buffing. Using the electric sanders (described in an earlier section) requires a glove on the hand that holds the stainless piece. You can get away with a Michael Jackson act here as the hand grasping the sander is pretty safe. There will be times when the sander will "jump" sideways and put a nice dirty cut in an ungloved holding hand. People are not as impressed with the blood on the stainless as you were when you put it there.

While dodging richoceting stainless missiles and avoiding losing finger pieces during spontaneous happenings is reason enough to wear gloves, most of the injuries I incurred (before learning to be safer) were burns. Gloves are a must. Either the sanding or the buffing can both heat the stainless enough to blister bare skin. Rubberized gloves will melt if used carelessly. Leather or cotton is the way to go depending upon the task. I like the cloth gloves with rubber gripping bumps for sanding and use leather gloves for the buffing wheel work.

A squirt bottle used when sanding will do three valuable things for you. One: It keeps the stainless cool and that has four values:

One: It keeps the worker from burns, Two: It keeps the stainless from warping (severe case). and Three: It keeps the stainless from getting discolored, and Four: It keeps the wooden bucks that hold the stainless from catching on fire. (We will cover the wooden bucks later.)

Let's see where were we?

Oh yeah, the second valuable thing is that the water mist keeps the sandpaper working well, just as it does when you are doing body work. I forgot what the third thing might be.

I have also tried misting the stainless piece during buffing and finally decided there was no measurable benefit there. ( I had a new theory at the time.)

Catfish saliva works really great in the squirt bottle. If you have trouble getting that, tap or well water will work just as well.

Discoloration of the stainless can be removed without much work. The discoloration is just a top layer of oxide where the hot metal and air met. It is surface only. A wheel cover burned from a hot wheel bearing can be 'made purty' again with a fine sanding and then buffing.

Don't do any wheel covers until they have been discussed in another thrilling Stainless Restoration post, which may also include using a simple child's toy to your benefit.

Shame on you for picking on a simple child.

I assume that since you are smart enough to run a computer then you are also smart enough to wear eye protection and a dust mask without me telling you it is a good idea.

Lark Parker Lark Parker

If at first you don't succeed -- you will get a lot of advice.

|

Edited by - Lark Parker on 01/18/2008 10:46:08 AM |

|